Oxygen enriched aquaculture

(Dissolved oxygen equipment)

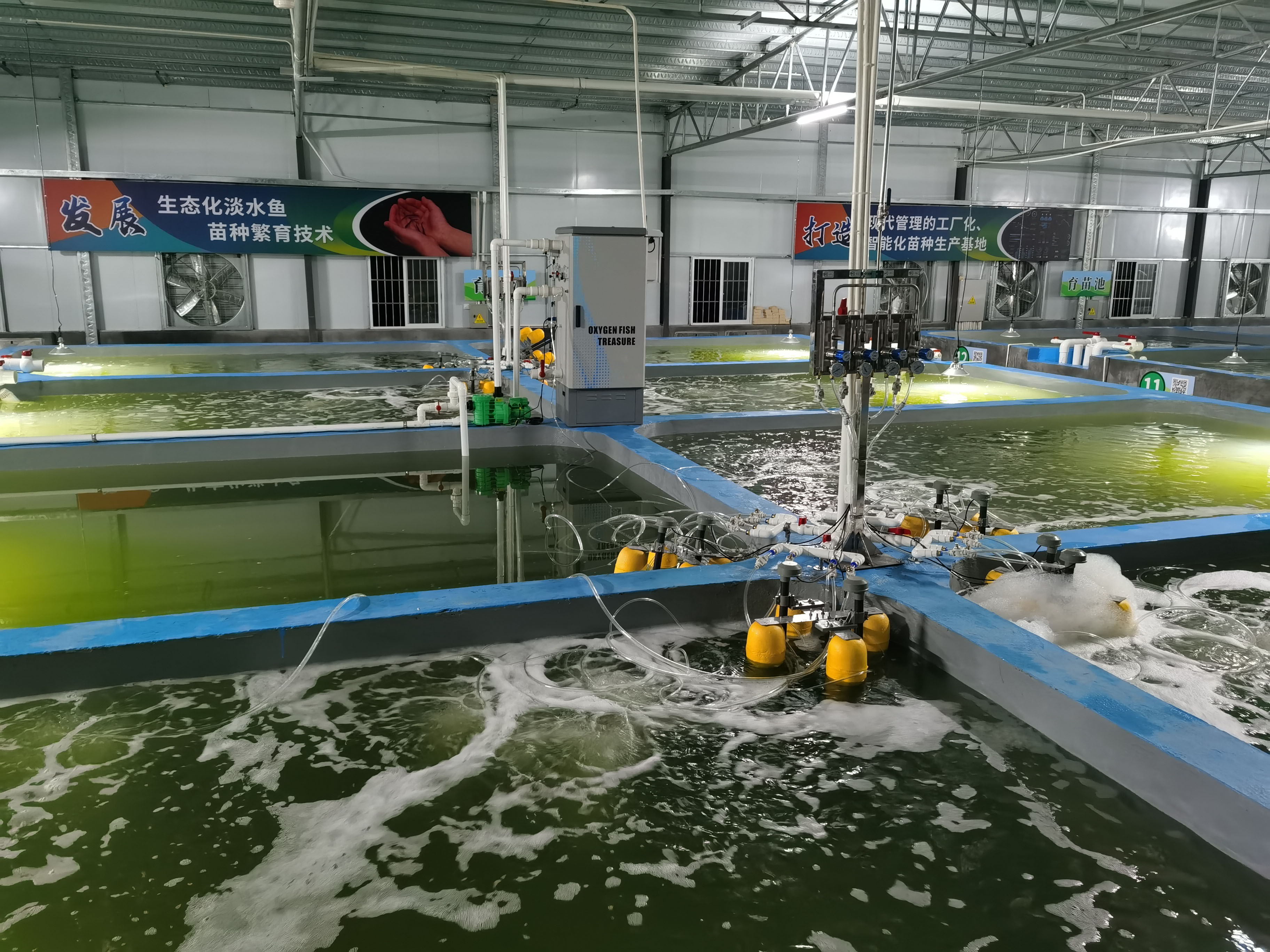

Conventional aquaculture uses oxygen pumps and compressed air to ensure oxygen supply to the water body, but in severe weather conditions such as thunderstorms and typhoons, power outages in soil ponds or aquaculture factories can lead to large-scale aquatic deaths caused by hypoxia.

In response to the above situation, our company has developed a set of dissolved oxygen aquaculture technology and equipment, which can prevent aquatic mortality caused by severe weather and oxygen deprivation. Simultaneously using our dissolved oxygen aquaculture technology can achieve functions such as increasing yield, reducing feed to material ratio, improving growth rate, lowering electricity consumption costs, reducing oxygen consumption, and automatic emergency oxygen supply in case of power outages.

Oxygen supply method: pure oxygen exposure, dissolved oxygen equipment

Applicable scenarios: Conventional soil ponds, factory breeding ponds, fish truck transportation

| Model | Specification | Accuracy | Main equipment included | Required supporting facilities |

| TOVO | 300-180-400mm | ±3mg/L | IoT control box, dissolved oxygen probe (electrode type), 220V (380V) AC contactor, oxygen output control valve, Dewar flask pressure monitoring probe, pH probe (optional), PLC control (optional) | Oxygen (Dewar flask/storage tank), pressure reducing valve, nanotubes/aeration disc, PVC/PPR gas pipe |

| T1V1 | 600-600-1600mm | ±2mg/L | IoT control box, dissolved oxygen cabinet, Dewar flask pressure monitoring probe, dissolved oxygen probe (electrode type), pH probe, water pump (one for backup and one for use) | Oxygen (Dewar flask/storage tank), pressure reducing valve, nanotubes/aeration disc, PVC/PPR gas pipe |

| T2V2 | 1000-1000-2200mm | ±2mg/L | IoT control box, dissolved oxygen cabinet, pH probe, water pump (one in use and one backup), PLC touch screen system (optional dual touch screen), dissolved oxygen probe (fluorescence), Dewar flask pressure monitoring probe | Oxygen (Dewar flask/storage tank), pressure reducing valve, nanotubes/aeration disc, PVC/PPR gas pipe |