About LPG Storage Tank

This is a comprehensive introduction about "LPG storage tanks". LPG storage tank, also known as liquefied petroleum gas storage tank, is a large pressure vessel used to store a large amount of liquefied petroleum gas (usually propane, butane or their mixtures).

The following is a detailed description of LPG storage tanks, covering their types, structures, safety systems, and key considerations.

Basic concept of LPG storage tank

LPG is gaseous at room temperature and pressure, but it liquefies into a liquid at a certain pressure or when the temperature is lowered. The volume of liquid LPG is only about 1/250 of that of gas, so for efficient storage and transportation, it needs to be stored in a specially designed pressure vessel in liquid form, which is the LPG storage tank.

Main types

According to the installation location and purpose, LPG storage tanks are mainly divided into the following categories:

Above ground storage tank

Advantages: Low construction cost, easy inspection, maintenance, and firefighting, good ventilation conditions, and low risk of combustible gas accumulation.

Disadvantages: Occupying ground space and being affected by external factors such as wind, rain, and sunlight, the landscape may not be coordinated.

Common applications: large industrial fuel stations, urban gas stations, refineries, automobile refueling stations, etc.

Underground storage tank

Advantages: It does not occupy ground space, is less affected by changes in ground temperature, has more stable pressure, higher safety (away from fire sources), and is aesthetically pleasing.

Disadvantages: High construction cost, extremely high requirements for anti-corrosion, and difficulties in inspection, maintenance, and leak detection.

Common applications: Gas supply stations in places with high requirements for space and aesthetics, such as residential communities, hotels, airports, etc.

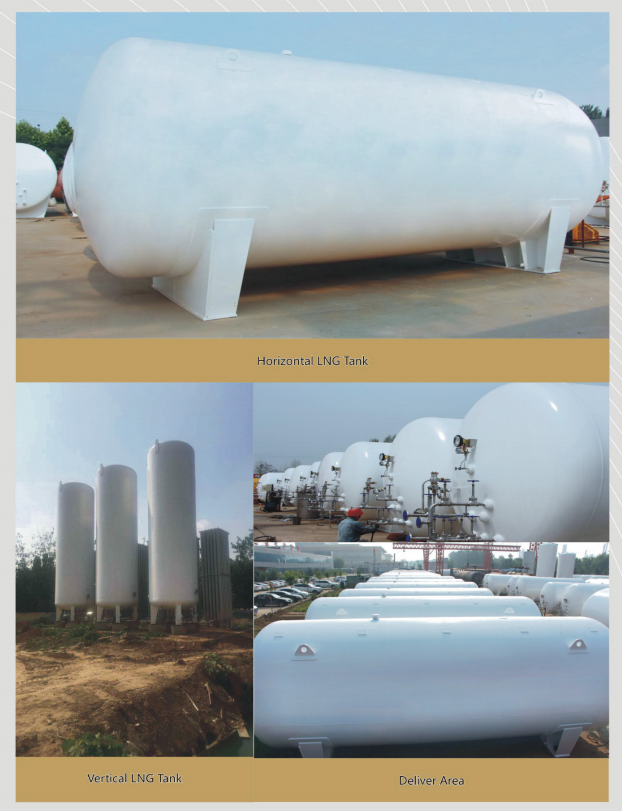

Cylindrical storage tank

This is the most common shape, divided into vertical and horizontal.

Horizontal storage tank: The most widely used, commonly used for small and medium-sized storage and above ground installation.

Vertical storage tank: more suitable for large storage capacity, can save floor space, but requires high foundation requirements.

Spherical storage tank

Advantages: Under the same volume, spherical shapes have the smallest surface area, good pressure resistance, low material consumption, and minimal evaporation loss.

Disadvantages: The manufacturing process is complex, the cost is high, and it is difficult to inspect and install accessories internally.

Common applications: Ultra large storage bases (such as receiving stations), in situations with high work pressure.

III. Main Structure and Composition

A complete LPG storage tank system not only includes the tank itself, but also a series of ancillary equipment:

Tank bodyMaterial: High strength low-alloy steel, such as 16MnR (16 manganese capacity), is usually used.

Design: Designed and manufactured according to pressure vessel specifications, taking into account design pressure, design temperature, corrosion allowance, weld coefficient, etc.

Thermal insulation layer: for LPG requiring low-temperature storage, there are cold insulation layer (such as polyurethane foam) and damp proof layer outside the tank.

Internal devicesLevel gauge: used for real-time display of the liquid level height inside the tank (such as magnetic flap level gauge, radar level gauge).

Anti vortex device: installed at the liquid outlet pipe to prevent the generation of vortices and the entrainment of gas during liquid extraction.

Pipeline and valve systemLiquid phase tube: used for outputting or inputting liquid LPG.

Gas phase tube: used for balancing pressure or outputting gaseous LPG.

Safety valve: It is a crucial safety device that automatically opens to release pressure when the pressure inside the tank exceeds the set value.

Emergency shut-off valve: In the event of a leak or fire, it can remotely or automatically quickly close the entry and exit of materials.

Drain valve: used to regularly remove impurities and water accumulated at the bottom of the tank. Instrumentation and Monitoring System

Pressure gauge: monitors the pressure inside the tank.

Temperature gauge: monitors the temperature inside the tank.

High liquid level alarm: When the liquid level reaches the set high level, an alarm is triggered to interlock and close the feed valve to prevent overfilling.

Combustible gas detector: installed around the storage tank area to monitor for LPG leaks.

Key safety systems and measures

Safety is the primary principle in the design of LPG storage tanks.

Fire prevention and firefighting system

Fire separation distance: The storage tank must maintain a safe distance as stipulated by regulations from other buildings and facilities.

Firefighting facilities: equipped with fixed water spray cooling system, fire hydrants, dry powder fire extinguishers, etc.

Fire dike: A fire dike is set up around the above ground storage tank to collect and contain leaked LPG liquid, preventing its spread. Leakage control and emergency system

Leak detection: Timely detection of leaks through gas detectors and manual inspections.

Emergency release system: In extreme situations such as fires, the gas inside the tank is guided to the flare or high-altitude safe venting through safety valves or rupture discs.

Water curtain system: used to dilute and disperse leaked gases.

Corrosion prevention and grounding

Anti corrosion coating: The inner and outer walls of the tank body need to have specialized anti-corrosion coatings.

Cathodic protection: For underground storage tanks, this is a necessary anti-corrosion measure.

Anti static grounding: Ensure that the tank and all metal components are well grounded to prevent static electricity accumulation and spark generation.

Key points of operation and maintenance

Filling operation: Strictly prohibit overloading (usually not exceeding 85% of the volume), leaving space for the liquid to expand when heated.

Regular inspection: According to the national special equipment safety regulations, qualified institutions must conduct regular inspections (such as annual inspections and comprehensive inspections).

Daily inspection: Operators need to regularly check the pressure, temperature, liquid level, valve status, and whether there are any signs of leakage.

Emergency plan: The operating unit must develop detailed accident emergency plans and regularly organize drills.

Summary

LPG storage tank is a complex system involving materials science, mechanical engineering, process control, and safety engineering. Every aspect of its design, manufacturing, installation, operation, and maintenance must strictly comply with relevant standards and specifications to ensure its long-term, safe, and stable operation, providing reliable energy security for both industrial and civilian sectors.

Air Separation Plant/Nitrous oxide plant/CO2 recovery plant/Hydrogen plant/Acetylene Plant/Mobile Tank/ISO Tank Container/Cryogenic Storage Tank/LPG Storage Tank/Cryogenic Pump/Micro Bulk Tank /Cryogenic Semi Trailer Transport Tanker/LPG Semi Trailer Tanker/Dewar Flask/Vaporizer/Cylinders/Dry ice making machine/Calcium Carbide

H2 plant Hypower Project wind power to H2 2000NM3 per hour (1).jpg)

.jpg)